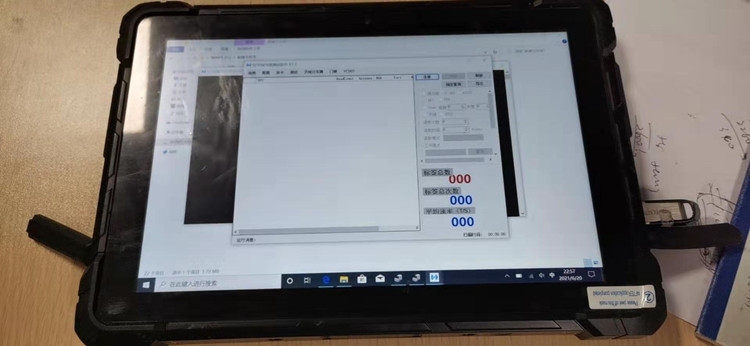

Application of handheld industrial tablet computer in tunnel measurement industry

The tunnel measurement industrial tablet computer is simple and efficient to operate through the software installed on the tablet computer. It can be connected to the scanner at the tunnel construction site for dense point cloud measurement, and the overall tunnel over-under-excavation analysis and secondary lining thickness analysis can be performed on-site to generate color levels. Vivid point cloud chromatogram; can generate cross-section over-under-cut and secondary lining thickness analysis diagrams at arbitrary intervals. The industrial tablet computer can also be connected to the total station on site. According to the data collected by the software and the analysis results of the target thickness, the scanner is driven to use the red laser point to indicate the corresponding area of the tunnel, so as to grasp the overall excavation progress of the tunnel in real time, and find out the existing problems in the tunnel construction process in time. question.

First of all, the inspectors use the total station to scan the three-dimensional data of the tunnel in a distributed manner, which can be used as an important basis for checking whether the construction meets the standards. Then, according to the on-site environment, the staff used a three-dimensional laser scanner to collect data with high precision to obtain comprehensive data information of the tunnel. At the same time, the instrument can detect the deformation of the tunnel, and quickly analyze data such as vault settlement, convergence state, over-under-excavation, and axis deviation in the tunnel monitoring measuring instrument. By comparing the cross-sectional data of the tunnel in different periods, the deformation trend of the tunnel can be found in a timely and accurate manner, providing data support for subsequent design parameter changes, construction method optimization, process adjustment, construction schedule arrangement, and construction quality control, ensuring construction safety and progress, while avoiding many Unstable factors and diseases have realized multi-directional and whole-process tunnel engineering quality inspection and survey.

In the era of digital interconnection, "connection" has become a basic capability. Intelligence has increasingly become the mainstream mode of the division of labor system in the digital age, and tunnel detection equipment such as subways is no exception. From manual detection to optical fiber technology to intelligent equipment, the detection equipment has gone through the whole process of intelligent technology detection from research and development to maturity to being put into use. A new model of technological integration industry development in the digital age is taking shape. In the future, with the support of digital technology, algorithm deduction, panoramic acquisition and other technologies, the inspection industry will also usher in more possibilities.

Using the industrial tablet computer installed with the intelligent detection system of subway tunnels, the system automatically performs real-time full-section scanning, and compares the scanning results with the standard limit data (including curve widening data) saved in the database in advance. The over-limit image will be displayed in real time and the sound and light alarm will be displayed, and the over-limit point will be recorded in the database for easy viewing, and the detection results will be saved at the same time. The system is intelligent, has a high degree of automation, has good scalability, and has high measurement accuracy, which improves the efficiency of on-site detection. Moreover, the equipment has a simple structure and a modular design, which is convenient for later maintenance.